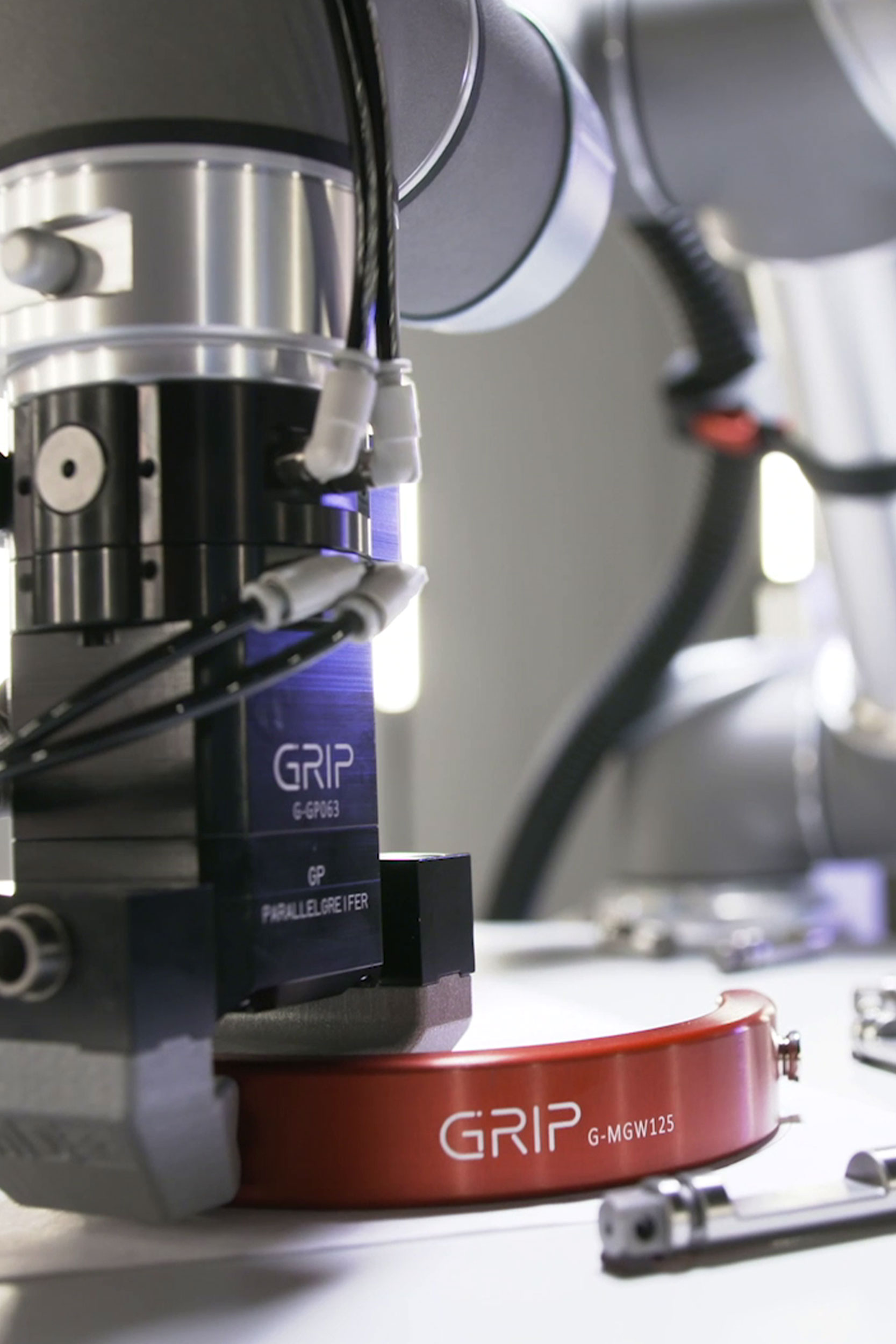

Tool changer for robots

Increase your productivity and connect a robot to the right tool quickly and easily. The GRIP tool changers create maximum flexibility with the highest level of safety.

- Innovation and quality since 1989

- Compatible with standard robot tools and grippers

- Resilient and long-lasting products

Talk to our experts about our different solutions.

Contact

Manual tool changers

Flexible tool changing in just a few steps – discover our manual tool changing systems.

With GRIP's innovative solutions, you can be sure that your robot systems are always state-of-the-art and ensure optimal functionality. Discover how our changing systems can revolutionize your production processes and why GRIP has been your ideal partner for advanced robotics solutions for 35 years.

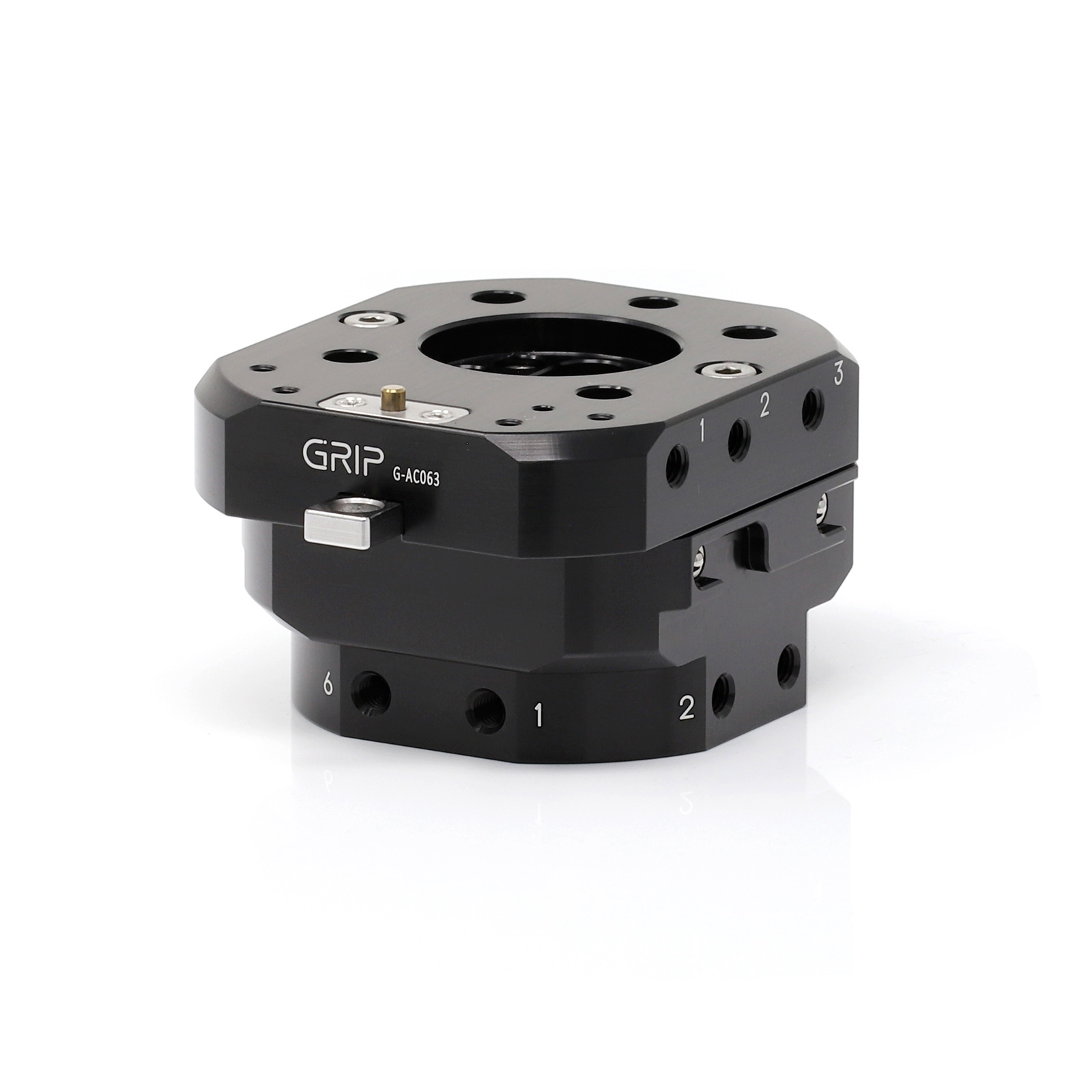

Automatic tool changers

Innovative, fully automatic tool change technology with the Auto Connector. Our most innovative solution for an automatic tool change without external energy.

More about the automatic changing systemTool changer systems for robots – functions

Manual and automatic tool changers, are critical components in the robotics industry that significantly increase the flexibility and efficiency of automated systems. Their main functions are:

- Increase in accuracy and improved quality: Automatic tool changing reduces human errors in tool alignment and assembly. This ensures more precise work and greater consistency in product quality.

- · Safety: Automated tool changing reduces the risk of injury by requiring less manual intervention and handling by human workers.

- Easy integration and maintenance: Our modern tool changers are designed to be compatible with all standard robot brands and models. They also require minimal maintenance, resulting in a longer service life and lower operating costs.

- Automatic tool or gripper changing: automatic tool changers allow a robot arm to automatically change tools or grippers without the need for human intervention. This expands the application possibilities of the robot.

- Increasing flexibility and expanding application area: Tool changers allow robots to perform a variety of tasks, from welding and cutting to assembly, inspection and packaging. The tool changing system makes a single robot versatile for different production processes.

- Improve productivity and efficiency: By changing tools quickly, production processes can be accelerated, and downtime minimized, resulting in higher overall productivity.

- Reduction in costs and space requirements: Instead of multiple specialized robots, a single robot with a tool changer can be used for different tasks, saving time and money while using up less space..

Our tool changers in help increase operational efficiency and flexibility while reducing production costs and improving the safety of production processes. When used in combination with cobots, collaborative robots, our tool changers a real asset to your company.

Trust the quality from the experts in handling technology. Talk to our experts about our different solutions. We look forward to your inquiry.

ContactTool changers: application areas

Tool changers are used in various industries and applications to increase the flexibility and efficiency of robot systems. The most important applications include:

-

Electronics manufacturing

-

Metal processing

-

Automotive industry

-

Plastic processing

-

Packaging industry

-

Pharmaceutical technology

-

Food industry

-

Logistics

-

Shoe industry